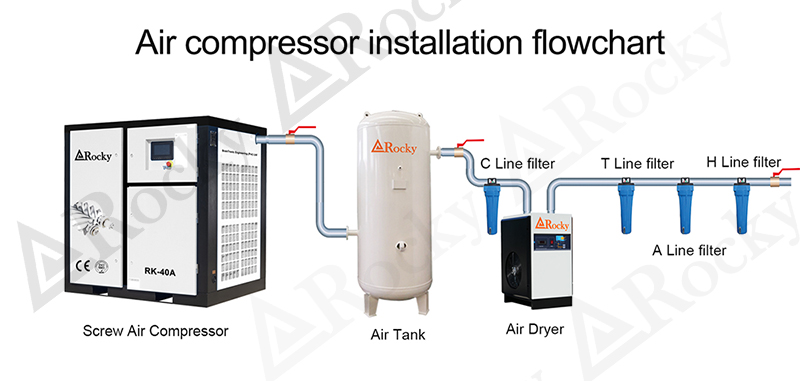

As the second largest power source in today's production, compressed air has been widely used in almost all manufacturing industries. As we all know, compressed air contains common impurities such as water, oil and dust. If it is not removed and used, it will cause damage to the equipment and affect the production process. How amazed with compressed air? Generally speaking, we connect the filter through the air storage tank, and then pass through the dryer to remove these impurities and provide clean compressed air for production.

Purifying compressed air has become an indispensable part of the manufacturing industry. In this system, the filter is used to treat oil and some solid particulate impurities, which are generally filtered through physical principles; machine to remove water from it.

The removal of moisture has always been a difficulty in purifying compressed air. From the previous refrigeration dryer to the popular use of adsorption dryers. People pay more and more attention to compressed air purification, but the cost of purification is also getting higher and higher.

The ultimate pressure dew point that can generally be reached by a refrigerated dryer is -20°C; an adsorption dryer can reach a pressure dew point of -70°C, which can basically meet all production gas quality standards.

So, in the compressed air purification process, which dryer should you choose? Which filter to choose?

The filter is basically a decontamination method, which is classified by the filtering volume; it is good to choose this according to the working conditions.

We know that the gas consumption and required quality of each enterprise are different. In general production, the pressure dew point of -20°C can meet the production needs. At this time, you can choose an affordable air dryer; If it is in industries such as painting, power plants, instrumentation, etc., which requires drier compressed air, then basically only adsorption dryers can be selected at this time.

Purifying compressed air requires such a complete system to continuously provide clean compressed air for enterprises, so as to minimize production costs, improve production processes, and ensure equipment stability.