An oxygen or nitrogen booster compressor is a specialized piece of equipment designed to increase the pressure of oxygen or nitrogen from an initial pressure to a higher pressure.

Key Features and Advantages

1. Ultra-Safe & Media-Compatible Design

Purpose-built for oxygen (combustible) and nitrogen (inert) gas properties.

Features oil-free, compatible materials (e.g., stainless steel, PTFE seals) throughout the gas path, eliminating

risks of fire or contamination and ensuring operational safety and gas purity.

2. Stable High-Pressure Output

Uses reciprocating piston or multi-stage technology to boost pressure up to 150-200 bar reliably.

Delivers a continuous, pulse-free gas supply, meeting stringent requirements for high-pressure filling, testing,

and lab applications.

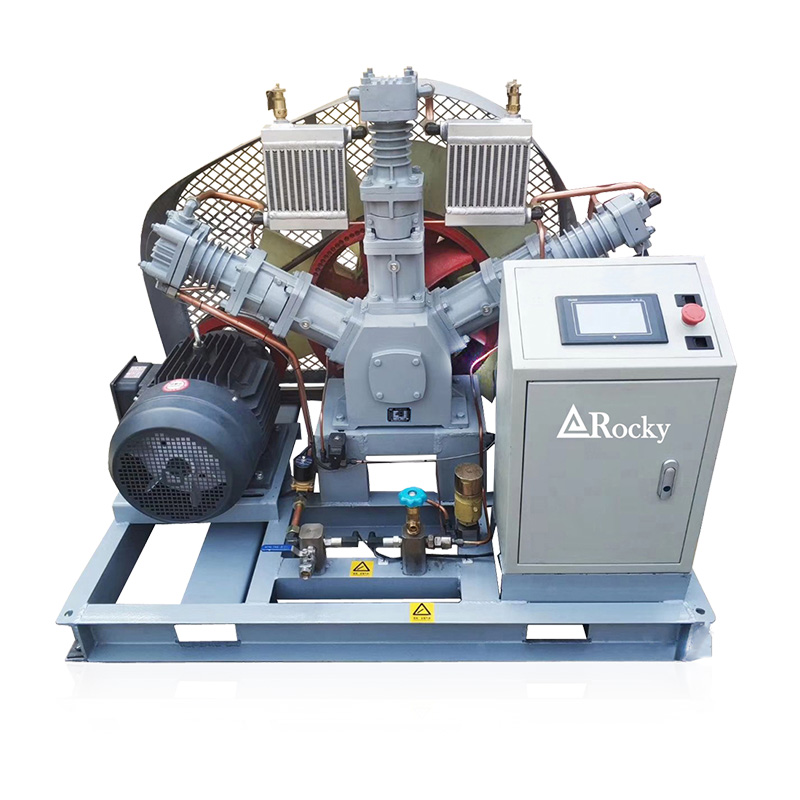

3. Compact & Adaptable Structure

Skid-mounted or modular design minimizes footprint.

Easily integrates into existing lines as a standalone filler or process booster, offering flexible deployment for

various scenarios.

4. Intelligent Control & High Reliability

Equipped with precision safety valves, sensors, and a PLC control system.

Enables auto operation, pressure preset, fault alarms, and safety interlocks for real-time monitoring and

protection, ensuring reliable performance with minimal operator intervention.

5. Efficient & Easy to Maintai

Incorporates high-efficiency drives (e.g., PM motors) and optimized cooling.

Maintains high energy efficiency while providing easy access to key components for inspection and replacement,

extending service intervals and lowering operating costs.

For technical support or inquiries, please leave your contact information.